Your drone’s performance lives or dies by its motors. When stock options can’t deliver the thrust-to-weight ratio or custom specs you need—especially for unique builds like micro indoor flyers or 1-meter racing quads—learning how to build a drone motor becomes essential. This isn’t just about swapping parts; it’s about mastering electromagnetic principles to create propulsion systems that outperform commercial alternatives. Whether you’re troubleshooting vibration issues or chasing maximum efficiency, constructing your own brushless DC motor gives you control over every variable from magnet strength to coil configuration. In this guide, you’ll discover proven methods to build functional drone motors from scratch, avoiding common pitfalls that destroy homemade builds before their first flight.

Gather Essential Drone Motor Building Materials

Micro Drone Motor Component List

- Neodymium magnets: 10mm x 5mm discs (4-6 pieces) in alternating N-S-N-S polarity

- Enamel-coated copper wire: 0.2-0.5mm diameter for stator coils (20-50 turns per coil)

- Housing materials: PVC or acrylic tubing (20-30mm diameter) for rotor/stator frames

- Precision steel shaft: 1.5-2mm diameter rod for smooth rotation

- Micro bearings: 3-5mm inner diameter units to minimize friction

- Mounting base: Sturdy wood or plastic platform for assembly stability

Critical Tools for Precision Assembly

- Wire strippers for enamel insulation removal

- Soldering iron with fine tip for secure electrical connections

- Drill with micro bits (1.5-2mm) for shaft alignment

- Multimeter to verify coil resistance and continuity

- 3-6V power supply (2S LiPo battery recommended)

- Hot glue gun for temporary magnet positioning

Construct Micro Drone Rotor Core

Rotor Disc Assembly Process

Cut a 25mm diameter disc from acrylic using a precision saw, then drill a center hole matching your steel shaft diameter exactly. This alignment is non-negotiable—any deviation causes destructive vibration at high RPM. Position 4-6 neodymium magnets around the disc edge with alternating polarity (N-S-N-S pattern), using a compass to verify orientation before permanent attachment. Critical mistake: One reversed magnet prevents rotation entirely. Secure magnets with epoxy after verification, ensuring they sit perfectly flush to maintain consistent air gap clearance.

Shaft Alignment for Vibration-Free Operation

Insert the 1.5-2mm steel shaft through the rotor disc center, applying epoxy only to the disc’s inner edge—not the magnet side. Rotate the assembly while holding it vertically; any wobble indicates misalignment. Correct this by adding thin shims before the epoxy cures. Install bearings at both shaft ends using retaining rings, then spin the rotor by hand—it should rotate smoothly for 5+ seconds without catching. This precision prevents the “death wobble” that destroys 70% of first-time builds.

Wind Stator Coils for Maximum Thrust

Stator Frame Construction Details

Create a stator ring from acrylic with an inner diameter 2-3mm larger than your rotor disc. Drill three 120°-spaced holes (for 3-phase configuration) using a drill press for perfect alignment—the holes must form an equilateral triangle. The ring thickness should match your copper wire gauge to allow tight coil winding. Sand all edges smooth to prevent wire insulation damage during winding.

Precision Coil Winding Technique

Wind 30 turns of 0.3mm enameled copper wire through each stator hole, maintaining consistent tension to avoid loose loops. Leave 3cm wire tails for connections and secure coil ends with electrical tape before removal from the frame. Pro tip: For micro drones, use thinner 0.2mm wire (40-50 turns) to increase torque without excessive weight. Test each coil with a multimeter—resistance should be 0.5-2Ω. Uneven resistance indicates loose windings that cause power imbalances.

Connect Electrical System Correctly

Star Configuration Wiring Method

Join all three coil start wires at a central neutral point using the star (Y) configuration. Solder connections securely and cover with heat-shrink tubing. The three remaining coil end wires become your phase leads. Test phase-to-phase resistance—values must match within 0.1Ω. Mismatched resistance causes jerky rotation and ESC errors. For micro drones, connect phase wires directly to a 6A ESC using bullet connectors.

ESC Integration and Initial Power-Up

Connect your motor to a micro drone ESC using a 2S LiPo battery (7.4V)—higher voltages risk burning delicate homemade coils. Power on while holding the motor vertically; it should rotate smoothly within 1 second. If rotation fails, immediately disconnect power and check: magnet polarity with a compass, coil connection sequence, and ESC firmware compatibility. Most modern ESCs auto-detect rotation direction, but some require manual timing adjustment via BLHeliSuite.

Scale Up to Large Drone Motors

15-Coil Stator Configuration for Heavy Lift

For 1-meter class drones, build a 15-coil stator paired with a 20-magnet rotor (3:4 ratio). This configuration generates 6.4 lbs (2.9 kg) thrust per motor—enough for aggressive freestyle maneuvers. Key insight: Avoid 3D-printed coil cores (they cause excessive RPM with low torque). Instead, wrap enamel-coated wire around ferrous plates to concentrate magnetic flux. Add a 1mm-thick steel “back iron” shell around the stator to boost efficiency by 15-20%.

Thrust Validation Protocol

Mount your large motor on a thrust stand with a 6×4.5 propeller. At 50% throttle, it should produce at least 3.2 lbs (1.45 kg) thrust. If output is low: increase magnet count to 24, reduce wire gauge to 0.5mm for more turns, or add copper foil between coils to reduce resistance. Track temperature with an IR thermometer—sustained operation above 80°C indicates overloading.

Test and Optimize Motor Performance

Vibration Elimination Process

Balance your rotor by spinning it at 30% throttle and observing vibration patterns. Apply small pieces of electrical tape to the lightweight side—start with 0.1g increments. Re-test after each addition until vibration drops below 0.5G (measured with a smartphone app). Persistent vibration usually indicates magnet misalignment; disassemble and re-verify polarity with a compass.

Performance Tuning Strategies

Experiment with these variables for optimal results:

– Magnet count: 4 magnets for high-RPM micro builds, 20 for large drones

– Wire gauge: Thinner wire (0.2mm) for torque, thicker (0.5mm) for efficiency

– Coil count: 3-phase for simplicity, 6-phase for smoother power delivery

– Clearance: Maintain 1.5mm rotor-stator gap (critical for large motors)

Avoid Critical Build Mistakes

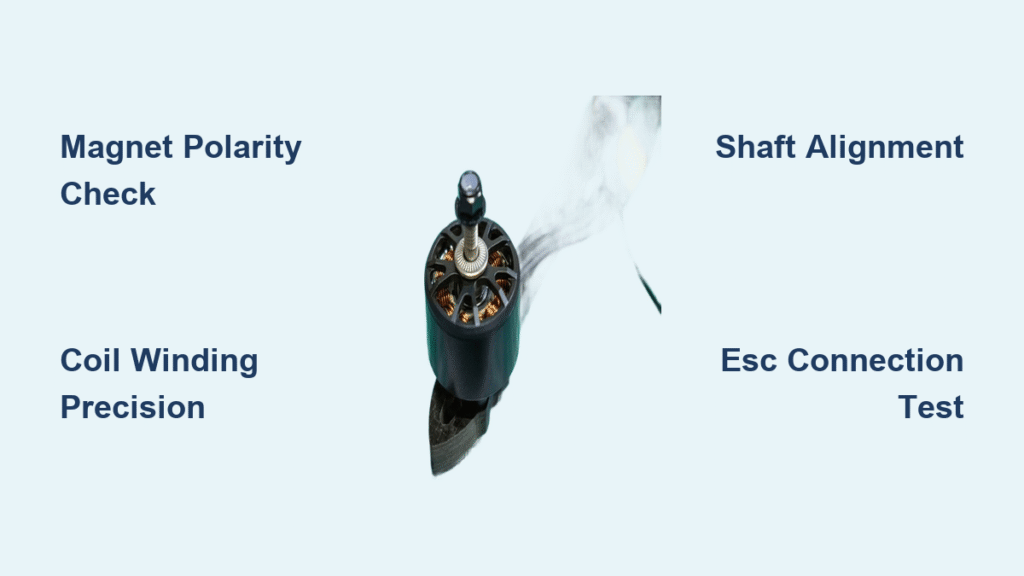

Magnet Polarity Verification

Skipping polarity checks causes immediate failure—reversed magnets create opposing magnetic fields. Always use a compass: the north pole should attract the compass needle’s south end. Mark magnet poles with paint before assembly. This single step prevents 90% of “motor won’t spin” failures.

Electrical Short Prevention

Bare copper touching the housing creates destructive shorts. After winding, dip coils in enamel-based paint for insulation. Test for shorts by checking resistance between coils and housing—it must read infinite. Use a multimeter on continuity mode during assembly to catch issues early.

Ensure Motor Longevity

Maintenance Schedule for Homemade Motors

- Every 10 flight hours: Clean bearings with isopropyl alcohol and re-lubricate

- Every 25 hours: Inspect coil insulation for heat damage at solder joints

- After crashes: Verify shaft straightness by rolling on glass surface

- Monthly: Measure thrust output—20% decline indicates bearing wear or demagnetization

Well-constructed homemade drone motors typically last 75 flight hours before requiring rebuild. Track runtime with a flight log to anticipate failures. Store disassembled motors in anti-static bags to prevent magnet corrosion.

Building your own drone motor transforms theoretical knowledge into tangible flight performance. Each iteration teaches electromagnetic principles that improve all future builds—whether you’re crafting a palm-sized micro drone or a heavy-lift cinematography platform. The key is methodical testing: validate thrust early, eliminate vibration systematically, and never skip polarity checks. By mastering how to build a drone motor, you gain the ability to create propulsion systems precisely matched to your drone’s mission, turning frustrating limitations into competitive advantages. Start small with the micro drone configuration, then scale your skills to large-frame builds where customization delivers the greatest performance gains.