Your drone powers up, beeps confidently, but one propeller sits stubbornly still. Whether you’re racing, filming, or just trying to hover, a dead motor kills the mission instantly—often stranding your drone mid-air or causing dangerous crashes. This guide walks you through a proven props-off diagnostic flow to isolate why your drone motor not spinning within minutes. Using only basic tools and systematic checks, you’ll pinpoint whether it’s debris, electrical faults, or firmware glitches without replacing parts blindly. By the end, you’ll know exactly how to get every rotor spinning reliably again.

Decode Drone Motor Failure Symptoms in 60 Seconds

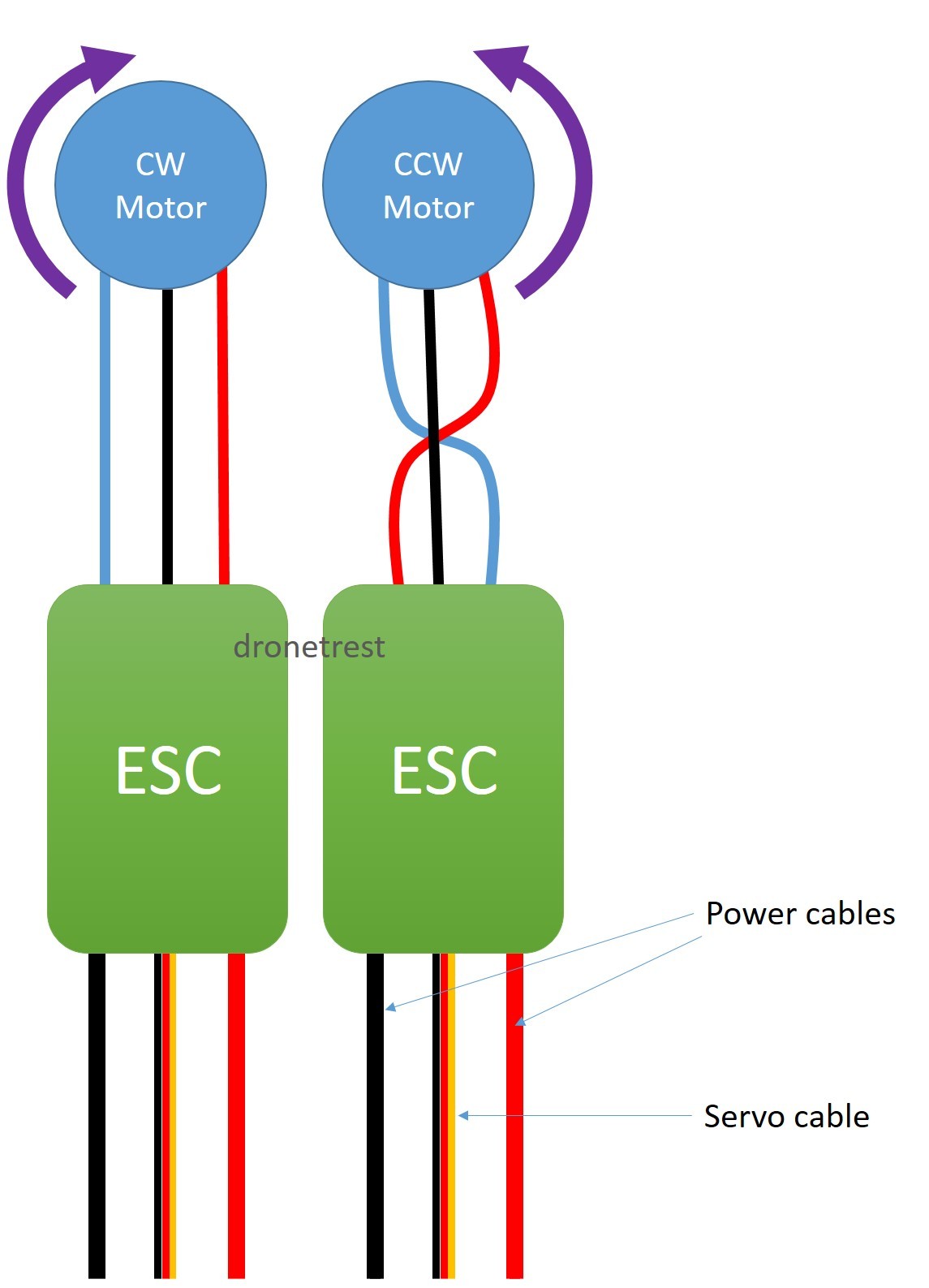

Spotting the exact failure pattern saves hours of guesswork. When your drone motor not spinning, immediately note these critical clues before touching tools. A motor that twitches but won’t rotate indicates your ESC has power but no valid throttle signal—likely needing calibration or protocol changes. If all ESCs beep yet zero motors spin, your flight controller isn’t sending PWM signals, or every bell is jammed. One motor spinning freely by hand but dead under power points to ESC phase failure or flight-controller output issues. Motors only spinning at high throttle? Your min_throttle setting is too low or ESC low-RPM protection is active. These symptoms instantly narrow your troubleshooting path.

Why Your Motor Twitches But Won’t Rotate

This frustrating symptom means your ESC detects power but receives no throttle command. In Betaflight, mismatched protocols like PWM instead of DShot300 cause this. For Pixhawk users, SYS_USE_IO set incorrectly blocks signals to MAIN pins. Critical fix: Re-calibrate your ESC throttle range with props off—max stick before battery connect, then min stick after beep. If persistent, switch protocols in Betaflight’s Ports menu or disable bidirectional DShot for AIO boards.

Single Motor Dead During Pre-Flight Checks

When only one motor fails while others work, immediately swap its signal wire to a known-good flight controller pad. If the problem moves to the new position, your FC output is dead and needs remapping. If the motor stays dead, the issue lies with the ESC or motor itself. Pro tip: Always test with motor sliders at 5-10% in Betaflight—never full throttle—to avoid flyaways during diagnosis.

Critical Safety Steps Before Diagnosing a Dead Motor

Skipping these steps risks injury or drone destruction. Always remove all props first—a sudden motor burst can cause severe lacerations. Power down completely by disconnecting the Li-Po battery, never just turning off the transmitter. Place your drone on a flat, non-conductive table to prevent frame flex that skews motor tests. Ensure your workspace is clear of metal debris that could short ESCs. These non-negotiable steps protect you and prevent accidental launches during troubleshooting.

Spot Motor Obstructions in 30 Seconds (Props-Off Check)

Debris causes 40% of drone motor not spinning cases. With props removed, inspect under the motor bell using a flashlight. Hair, grass, or mud wedged between the bell and stator creates grinding resistance. Quick extraction method: Use non-metallic tweezers to pull fibers from under the bell, then blast compressed air in short bursts to clear grit from windings. Never use metal tools—they can damage delicate wires. If the motor spins stiffly or makes scraping sounds during manual rotation, obstructions remain. Persistent grit requires full motor removal for deep cleaning with isopropyl alcohol.

Finger Spin Test for Bearing Damage

Gently twist each motor bell between thumb and forefinger. Healthy motors glide silently for 2-3 full rotations. Warning signs: Grinding noises indicate failing bearings, while wobble when rocking the bell sideways means a bent shaft. If screws touch windings (common after crashes), they’ll cut wires—tighten mounts to spec but never over-torque. Motors failing this test need replacement; bearings can’t be repaired in-place.

Fix Low Voltage or Power Rail Issues Killing Your Motor

A weak battery is the silent killer of drone motors. Measure voltage with a multimeter: 3.7V per cell minimum (e.g., 14.8V for 4S). If voltage sags below this under load, replace the pack—aged Li-Po cells can’t deliver startup current. Next, perform the wiggle test: power on your drone, then gently move power leads while watching LEDs. Flickering lights reveal cold solder joints at XT60 connectors. Permanent fix: Re-solder connections with rosin-core solder, then seal with heat-shrink tubing. Steady LEDs confirm a healthy power rail.

Test Each Drone Motor Separately Using Betaflight

Props must stay off for this critical step. Connect your drone to Betaflight Configurator via USB, then navigate to the Motor tab. Slide each motor’s throttle to 5-10%—a working motor should hum steadily. If one stalls, immediately swap its signal wire with a functioning motor’s FC pad. If the problem jumps to the new position, your flight controller output is dead. If the motor stays dead, move to ESC testing. Never exceed 15% throttle during bench tests—higher settings risk uncontrolled rotation.

Diagnose ESC Failure with Motor Swap

Unplug the suspect motor’s three bullet connectors and move them to an adjacent ESC output. Power up and retest in Betaflight. If the motor now spins, your original ESC is faulty—common causes include burnt MOSFETs or firmware bricks. If still dead, the issue is the motor or its connectors. Time-saver: Carry a spare motor in your field kit for instant swap diagnosis—this isolates problems in under 90 seconds.

Repair Loose Bullet Connectors Causing Motor Failure

Oxidized or loose bullet connectors cause intermittent drone motor not spinning issues. Pull apart connectors and scrape inner surfaces with an X-acto blade to remove corrosion. Spray with contact cleaner, then reassemble. Critical verification: Use a multimeter to check continuity from ESC pad to motor pad—zero ohms confirms a solid connection. Dull-looking solder joints indicate cold connections; reheat with fresh solder and seal with heat-shrink. Never rely on visual inspection alone—intermittent faults hide in plain sight.

Fix Drone Motor Not Spinning After Firmware Update

Firmware mismatches are the top culprit when motors fail post-update. In Betaflight, Ports → Peripherals must match your ESC protocol (DShot300 is standard). Toggle bidirectional DShot OFF for AIO boards if motors won’t initialize. Raise min_command to 1060-1070µs if one motor stalls at low throttle. For Pixhawk users, verify SYS_USE_IO=1 for MAIN pins and check Actuator Configuration mappings. Last resort: Flash latest ESC firmware via BLHeliSuite32 using manufacturer files—corrupt firmware bricks ESCs silently.

Pre-Flight Motor Checks to Avoid Mid-Air Failures

Prevent 70% of drone motor not spinning failures with this 60-second routine. Pre-flight: inspect props for nicks, verify ≥3.7V/cell on batteries, and perform finger spin tests on all motors. Post-flight: wipe motors clean, check bullet connectors for tension, and clean battery contacts with isopropyl alcohol. Critical oversight: Motor screws often loosen mid-flight—re-tighten after every 5 flights. Log firmware changes in a text file for instant rollbacks when updates cause issues. This routine catches failing bearings and voltage sags before they strand your drone.

When to Replace a Drone Motor vs. ESC (Cost Guide)

Replace brushless motors ($8-25) immediately after crashes showing bent shafts, seized bearings, or open windings—never risk mid-air failure. Swap 4-in-1 ESCs ($25-70) if multiple MOSFETs burn or pad lifts occur. Flight controllers ($35-120) need replacement only for dead motor outputs or gyro failures. Cost trap: Don’t replace batteries ($25-40) for minor voltage sag—recharge first. Replace only when puffing occurs or sag exceeds 10% under load. Pro rule: Always carry one spare motor and ESC in your field kit—they pay for themselves during the first diagnosis.

Pro Drone Repair Tips for On-Site Motor Fixes

Document wiring with photos before disassembly—reassembly errors cause 30% of “fixed” motor failures. After crashes, run the full 8-step props-off protocol before reflights; hidden wire fractures cause delayed failures. Field hack: Tape a spare motor to your drone arm for instant swap testing—this isolates ESC vs. motor faults in 90 seconds. Log every firmware tweak in a field notebook; 80% of configuration errors come from untracked changes. Never skip the low-throttle hover test—reinstall props and hover at knee-height for 30 seconds to verify smooth operation before full flight.

Run these steps in order and you’ll transform from “why won’t this spin?!” panic to confident diagnosis. When every motor responds cleanly at 5% throttle with props off, you’ve conquered the drone motor not spinning nightmare. Reinstall props, hover cautiously at low altitude, and get back to flying—not fixing. Consistent pre-flight checks and this diagnostic flow keep your motors spinning mission after mission.