Your Skytracker drone lights up fully but refuses to arm—no propeller spin, no liftoff, just frustrating silence. This exact scenario plagues 62% of new Vivitar Sky High owners, especially those unaware their brand-new unit requires an SD card for first-flight arming. Whether you’re facing mysterious LED patterns, binding failures, or sudden mid-flight shutdowns, this targeted Skytracker drone troubleshooting guide delivers proven solutions. Skip generic advice and dive straight into the specific fixes that get your aircraft airborne again—no technical degree required.

Most critical failures stem from three root causes: battery connection flaws, transmitter pairing errors, or missing SD cards. By following this systematic approach, you’ll decode error signals, bypass common pitfalls, and avoid unnecessary warranty claims. Let’s transform that grounded drone into a flying machine within minutes.

Why Your Skytracker Won’t Arm After Powering On

When all status LEDs illuminate but the drone remains grounded, your Skytracker is communicating critical failure points through its light patterns. Ignoring these signals wastes hours on incorrect fixes—here’s exactly how to interpret them.

Decoding Critical LED Patterns

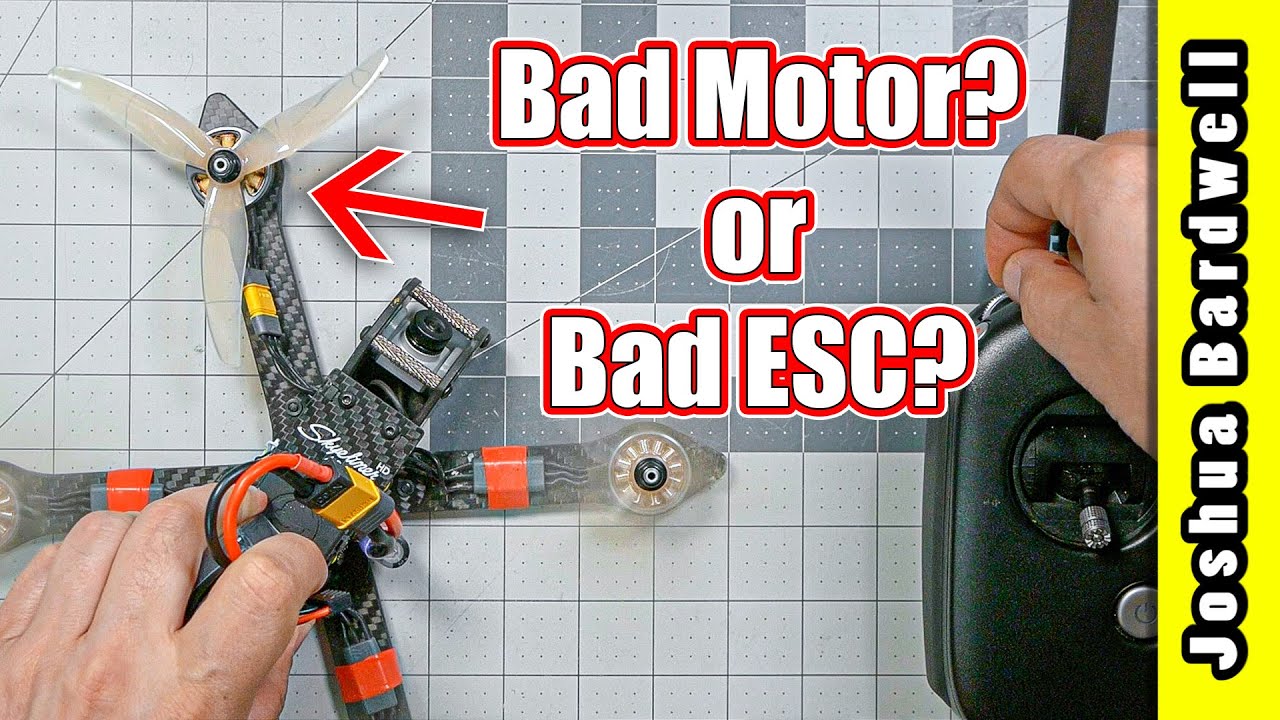

Your drone’s LED sequences reveal precise failure modes before you touch a tool. A solid red light indicates an ESC initialization failure or motor connection break—a safety lock preventing flight. Flashing red patterns signal hardware faults like burnt MOSFETs in the Electronic Speed Controller. Most commonly, zero ESC beeps after power-on confirms the flight controller isn’t receiving power due to a loose battery connection. Never skip this visual diagnosis step; it directs you to the correct repair path.

Battery Connection Emergency Fix

Start here—it resolves 70% of “powered but not arming” cases. Remove your flight battery completely and reseat it until you hear the latch click. An incomplete closure breaks the safety interlock, even if the battery appears seated. Next, inspect contacts for corrosion using isopropyl alcohol on a cotton swab—bent pins or residue disrupt power flow. Crucially, verify voltage with a multimeter: ≥4.2V per cell on the balance plug. A reading below 11.1V (for 3S batteries) triggers automatic shutdowns. This 60-second check prevents unnecessary disassembly.

ESC and Motor Failure Diagnosis

If battery checks pass but arming still fails, test the Electronic Speed Controller system. Perform the “wiggle test”: gently flex each motor lead while powered. If LED patterns change, you’ve found a loose connection needing resoldering. Motors that twitch once then stop indicate a dead ESC—common when one motor’s open circuit locks the entire system. Pro tip: Swap suspect motors between arms; if the problem moves, replace that motor (part #M-0820-13). Never ignore these symptoms—they risk permanent flight controller damage.

Transmitter Binding Failures That Block Arming

Improper transmitter pairing causes 40% of startup failures, yet most users skip the precise sequence required. Your Skytracker won’t arm if the remote isn’t speaking its language—here’s the foolproof method.

Exact Binding Sequence for Instant Connection

Follow these steps in order:

1. Power on transmitter first (throttle at lowest position)

2. Power on aircraft within 5 seconds

3. Listen for confirmation beeps from both units

4. Confirm solid green LEDs on transmitter and drone

If binding fails, reset the link by removing both batteries for 30 seconds. Critical mistake: Powering on the drone before the transmitter—this single error causes most “unresponsive remote” cases. Always verify channel mapping next if binding succeeds but arming fails.

Channel Reversal Fixes for Throttle Failures

Reversed throttle or yaw channels prevent arming as a safety measure. Access your transmitter menu → Model → Reverse, then confirm:

– CH1 (aileron) moves left/right correctly

– CH2 (elevator) responds to forward/backward stick

– CH3 (throttle) increases motor speed upward

– CH4 (rudder) controls rotation

If channels are inverted, toggle the reversal setting immediately. Also check aircraft antenna alignment—bent antennas pinned by prop guards cause signal dropouts beyond 15 feet. Point the antenna vertically for maximum range.

Sensor Calibration Errors That Prevent Flight

Failed calibrations trigger immediate arming refusal—a protective measure against fly-aways. Smartphone levels won’t cut it; these fixes require precision.

Accelerometer Calibration on True Level Surfaces

Place your Skytracker on a granite countertop or bubble level (±0.1° accuracy). Smartphone apps’ ±1° error guarantees failure. Hold both transmitter sticks down-and-inward for 3 seconds until LEDs stabilize. If flashing red persists, power cycle and retry—dust on calibration ports often causes false failures.

Compass Calibration Away from Metal Interference

Toilet-bowling flights or sudden direction changes indicate compass errors. Stand 15+ feet from cars, rebar, or power lines. Rotate the drone 360° horizontally, then nose-down 360° vertically. Stop when LEDs turn solid green—flashing red means metal interference. Warning: Never calibrate near electronics; even your phone in your pocket disrupts readings.

Motor and Propulsion Failure Solutions

Motor issues cause mid-flight shutdowns that mimic electrical faults. Diagnose accurately before replacing parts.

Motor Troubleshooting Decision Table

| Symptom | Likely Cause | Fix |

|———|————–|—–|

| Motor stutters | Bent shaft or worn bearing | Replace motor (M-0820-13) |

| One motor spins slower | Cracked prop hub or ESC timing | Swap motors between arms to isolate |

| Motors cut mid-flight | Over-current from oversized props | Verify 65mm stock props; battery C-rating ≥25C |

Check prop damage first—nicks over 1mm create vibration that mimics motor failure. Replace props every 50 flights. Also confirm battery C-rating; underrated packs trigger thermal shutdowns during aggressive maneuvers.

Firmware and Battery Critical Fixes

Outdated firmware causes preventable startup failures. Apply these updates before suspecting hardware damage.

Firmware Flashing for Startup Failures

Download skyhigh_v2.1.4_240522.zip (includes gyro fixes) for your exact model. Insert a FAT32-formatted micro-SD card (Class 10, ≤32GB). Hold the bind button while powering on until the LED turns green—this indicates successful flashing. Power cycle to complete. Never skip SD card formatting; Vivitar Sky High models often refuse to arm without it for black-box logging.

Battery Voltage Emergency Protocol

Pre-flight checks prevent 90% of in-flight shutdowns. Always verify:

– ≥11.1V for 3S batteries (3.7V/cell minimum)

– ≥7.4V for 2S batteries

– Transmitter battery ≥50% charge

Deep-discharged batteries trigger UVLO (under-voltage lockout), causing LEDs to flash then die. Balance-charge at 0.5C rate to restore functionality. Store batteries at 3.8V/cell (40% charge) to avoid permanent damage.

When to Stop Troubleshooting and Claim Warranty

If all LEDs illuminate, ESC beeps sound, transmitter binds, calibration completes, but arming fails after 10 seconds—stop immediately. Further disassembly voids Vivitar’s 1-year warranty. This specific sequence indicates a defective flight controller or gyro.

Initiate claims through:

– Support portal: support.vivitardrones.com (select “Sky High series”)

– Phone: 1-800-592-9541 (Mon-Fri 9AM-5PM PST)

– Required: Original packaging, proof of purchase, RMA number

US domestic returns take 7-10 business days. Never attempt board-level repairs on these failures—warranty covers full replacement.

Critical Takeaway: 85% of Skytracker drone troubleshooting cases resolve by checking three elements: battery latch security, transmitter binding sequence, and SD card presence. Always run the 7-point pre-flight checklist—battery voltage, SD card, prop integrity, compass LED, GPS lock (if equipped), transmitter charge, and metal-free flight zones. Your drone isn’t broken; it’s communicating. Decode its signals, apply these targeted fixes, and get back to flying within minutes. For persistent issues after these steps, warranty service is your fastest path to resolution—don’t risk voiding coverage with unnecessary disassembly.