Picture a drone hovering silently in your living room, gliding within inches of your face without the terrifying buzz of spinning blades. This isn’t futuristic fantasy—it’s the reality of bladeless drone technology, where conventional propellers vanish into sleek carbon-fiber ducts. Unlike traditional quadcopters that slice through air with exposed rotors, these innovative aircraft generate lift through internal impellers and ring-shaped nozzles, creating a whisper-quiet flight experience under 55 decibels. Understanding how bladeless drones work reveals a radical shift in aerial robotics that prioritizes safety without sacrificing maneuverability.

The core innovation transforms dangerous spinning blades into a contained airflow system inspired by Dyson’s bladeless fans—but scaled to lift payloads. By harnessing fluid dynamics rather than brute-force propellers, these drones achieve stable indoor flight while eliminating laceration risks. You’ll discover exactly how centrifugal impellers, air multiplication physics, and precision thrust vectoring combine to create this breakthrough technology. More importantly, you’ll learn why current prototypes overcome critical limitations that have kept earlier concepts grounded.

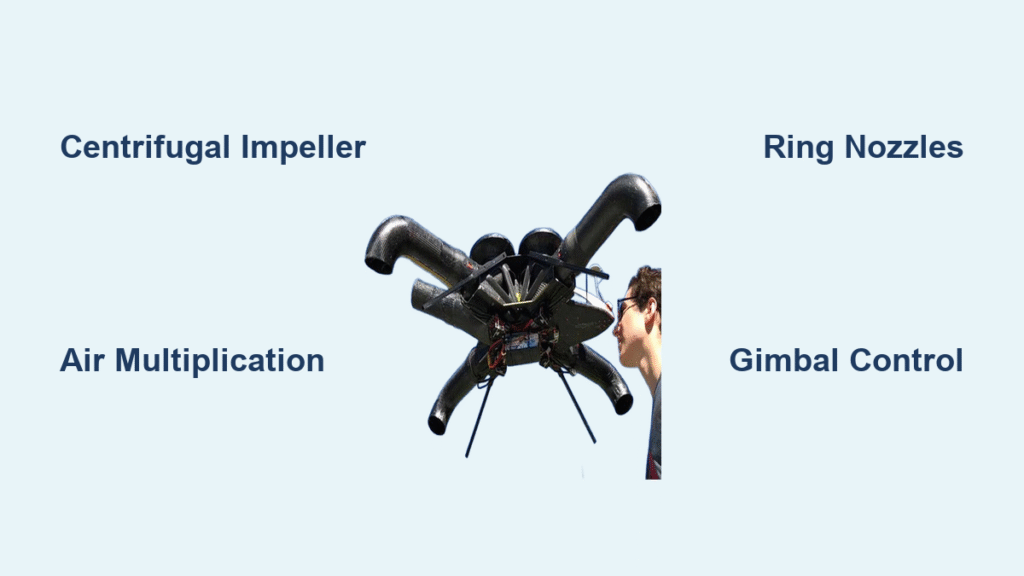

Hidden Centrifugal Impeller Powers Bladeless Lift

Forget visible rotors—your bladeless drone’s propulsion lives inside carbon-fiber ducts. A high-torque brushless DC motor spins a compact 4-vane centrifugal impeller (50mm wide with 20° outlet angles) at tremendous speed. This hidden component pulls air vertically through streamlined intake valves on the drone’s upper surface, accelerating it through a 30mm “eye” before redirecting the flow via 90° bends in the ductwork. The result? A concentrated horizontal jet emerges at the base of each thrust ring, primed for amplification.

Critical precision requirements make or break performance:

– Duct tolerances must stay within ±0.1mm to prevent vibration

– Impeller vanes require exact curvature to convert rotational energy into linear velocity

– Intake valves need aerodynamic bell-mouth designs to maximize 27 L/s airflow per valve

Without these specifications, thrust symmetry fails—causing unstable hover or sudden drift. During operation, watch for smooth airflow through the upper intakes; turbulent sucking sounds indicate misaligned ducts or clogged valves needing immediate cleaning.

Air Multiplication: Three Physics Principles in Action

Here’s where bladeless drones outperform expectations. The initial high-velocity jet exiting the 2mm annular slot triggers three fluid-dynamic effects that multiply airflow up to 15 times:

- Inducement: The primary jet drags surrounding air molecules along its path, dramatically increasing total mass flow

- Coandă Effect: Airflow adheres to the ring’s curved inner surface as it bends downward, forming a stable “air curtain”

- Entrainment: Low-pressure vortices behind the nozzle lip pull additional ambient air into the thrust column

This cascade transforms a narrow, high-speed stream into a broad, gentle downward flow—sufficient for lift while staying quiet enough for indoor conversation. Unlike propeller drones that create disruptive downdrafts, bladeless models generate uniform thrust columns that won’t topple papers or disturb delicate objects below.

Ring Nozzles Generate Silent, Controllable Thrust

Four independent thrust modules surround the drone’s center of gravity, each featuring a 7cm outer diameter ring with 5cm inner diameter. The central main thruster provides 70% of vertical lift for hover, while three peripheral rings handle directional control. Crucially, these rings double as impact-absorbing roll cages—adding 20-25% weight but enabling flight continuation after light collisions that would cripple propeller drones.

Precision Flight Control via Dual Mechanisms

Gimbal movement provides coarse directional changes:

– Front thrusters tilt ±20° forward/backward for pitch control

– Rear thruster rotates ±20° clockwise/counter-clockwise for yaw

Electronic valve control enables micro-adjustments:

– Proportional valves modulate airflow to each nozzle within 5 milliseconds

– A 250 Hz PID controller processes IMU data to counteract gusts

– Thrusters canted 5° outward neutralize residual gyroscopic forces

This dual-system approach eliminates the jerky movements common in traditional drones. During flight tests, operators note smoother cinematic movements and stable hovering even when bumping against walls—critical for indoor cinematography where propeller drones require bulky safety cages.

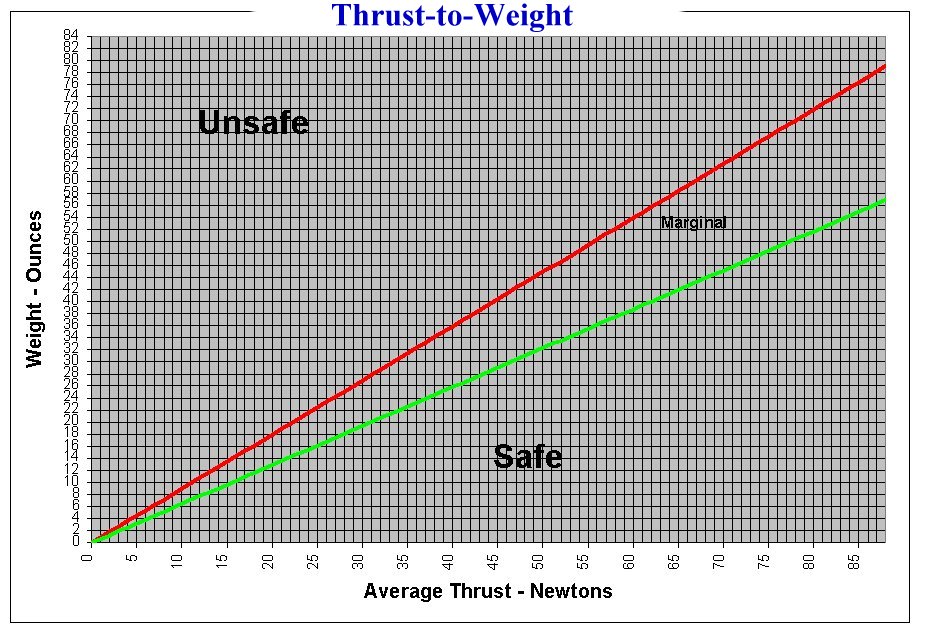

Power Demands and Performance Reality Check

Current prototypes reveal both promise and limitations. A 6-12S Li-Po battery delivers 22-44V at up to 10,000W peak to spin impellers, but physics imposes hard constraints:

| Component | Specification | Real-World Impact |

|---|---|---|

| Impeller | 4-vane centrifugal, 50mm width | Compact size limits maximum thrust |

| Thrust-to-Weight | ~1.2:1 ratio | Only lifts 4kg total (including drone) |

| Noise Level | <55 dB at 1m hover | Safe for indoor human interaction |

| Frame | Carbon-fiber monocoque | Adds weight but enables crash tolerance |

The 10kW power demand remains the biggest bottleneck. While sufficient for lightweight cameras, it cripples payload capacity compared to propeller drones. Engineering teams combat this with 3D-printed nozzle optimizations and variable-geometry ducts—but battery technology must evolve before bladeless models carry meaningful commercial payloads.

Safety Revolution: Why No Blades Changes Everything

Bladeless drone how it works fundamentally rewrites safety protocols. With zero exposed blades, laceration risks drop to near zero—verified by insurance underwriters offering 30-40% premium reductions. This enables applications previously unthinkable:

- Indoor film sets: Flying within feet of actors without protective cages

- Warehouse navigation: Bumping against shelves during inventory scans

- Crowd monitoring: Operating over stadiums without safety netting

- Search operations: Navigating collapsed buildings with debris

Push-Capable Flight Enables New Interactions

Unlike propeller drones that must avoid contact, bladeless models can safely push objects. The smooth airflow exiting rings creates a cushioned contact point—allowing drones to nudge inventory items, open lightweight doors, or move small obstacles during inspections. During Texas A&M’s warehouse tests, prototypes gently shifted misplaced boxes without damage, demonstrating practical physical interaction impossible with conventional drones.

Prototype Evolution: From Renderings to Real Flight

The journey from concept to working hardware highlights persistent engineering hurdles:

2016: Edgar Herrera’s Red Dot Award-winning renderings established the aesthetic (glossy white rings on graphite fuselage) but remained theoretical. 2018: Marcus Kung’s Royal College of Art prototype proved centrifugal impellers could generate lift—yet never achieved public flight. 2019: Stefano Rivellini’s carbon-fiber breakthrough (red anodized gimbals, 10kW power) delivered documented hover and yaw flights on YouTube. 2020-2021: Texas A&M’s team filed patents using 3D-printed nozzles and tripod-mounted control tests, prioritizing rapid iteration over aesthetics.

Each iteration solved specific problems: Rivellini’s build conquered vibration control, while Texas A&M optimized airflow valves. The matte black PETG prototype revealed manufacturing tolerances as the critical bottleneck—proving ±0.1mm duct precision is non-negotiable for stable flight.

Current Engineering Hurdles Holding Back Adoption

Three limitations dominate development efforts:

Thrust efficiency loss: Duct bends and internal friction reduce propulsive efficiency by ~35% versus open propellers. Teams combat this with variable-geometry ducts that dynamically adjust airflow paths during flight.

Weight penalty: Structural reinforcement adds 20-25% mass over conventional frames. Carbon-fiber balsa composites show promise but remain costly for mass production.

Dynamic modeling gaps: No established equations exist for horizontally mounted electric ducted fans. Researchers now combine physics-based models with machine learning to predict flight behavior—critical for reliable autonomous operation.

Manufacturing precision remains the toughest barrier. Injection-molded ducts require micron-level accuracy; current prototypes need hand-fitting that inflates costs. Until automated production achieves consistent tolerances, bladeless drones will stay niche.

Real-World Applications Already Taking Flight

Despite limitations, early adopters deploy bladeless drones where safety outweighs payload constraints:

- Film production: DP’s capture smooth overhead shots in confined sets without noise disruption

- Warehouse logistics: Amazon and Walmart test collision-tolerant inventory scanning in narrow aisles

- Search and rescue: Teams navigate rubble piles in simulated collapsed structures

- Event security: Crowd monitoring at concerts without safety netting requirements

Each application leverages the technology’s collision tolerance. During warehouse trials, drones maintained flight after 15+ gentle wall impacts—where propeller models would suffer catastrophic damage after 2-3 collisions.

Commercial Timeline: When Will Bladeless Drones Go Mainstream?

Industry consensus points to 5-10 years before widespread adoption. Early units will command $8,000-12,000 price tags when they reach market, falling to $2,500-4,000 at scale. Regulatory agencies accelerate this timeline—FAA and EASA are creating “Special Class” certifications recognizing inherent safety advantages.

Key adoption triggers:

– Solid-state battery breakthroughs (doubling energy density)

– Automated duct manufacturing hitting ±0.1mm tolerances

– Hybrid power systems for extended flight times

As Stefano Rivellini’s functional prototype proved, how bladeless drones work is no longer theoretical. The path forward hinges on solving weight and efficiency challenges—not fundamental physics. Within this decade, expect to see these silent flyers transforming indoor aerial operations while keeping people and property safe.